ISO, DIN, and CEN standards and the FEPA regulations

Technical information about grinding

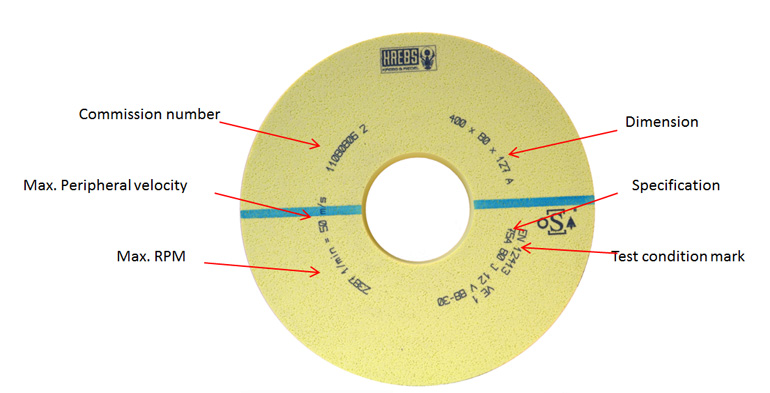

In agreement with manufacturers of grinding wheels which is in accordance with the ISO, DIN, and CEN standards and the FEPA regulations, each wheel contains the following information:

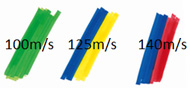

Safety Colour coding:

The inspected wheel must be completely dry

Preparation of the wheel for its use

Upon delivery check the packaging and the content of your shipment, i.e. the grinding wheel you ordered. Also inspect the dimension labels and any possible damages caused during transport.

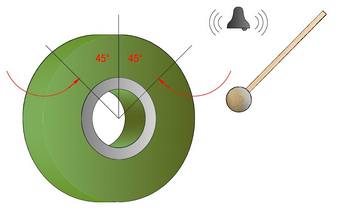

Directly before assembling a new or used vitrified grinding wheel it is necessary to perform a sound test. This is done by tapping it with a non metallic hammer. Light grinding wheels are held manually or are hung on a holder, while harder ones are set up vertically on the ground. The inspected wheel must be completely dry.

The sound or percussion test is performed on the left and the right side of the wheel at 45° from the central line.

The next step is to knock the wheel gently with either a non metallic or wooden percussion or a non metallic hammer and listen to the produced sound. If the wheel is intact, the sound of the knock will be sounding, on the other hand, if the sound produced is muffled and hollow, this means there is a crack in the wheel and it should not be used.

Wheels bonded in synthetic resin bond do not have as crisp and clear sound as wheels in vitrified bonds.

Machinery flanges should be clean and intact

Flange assembly

Before using the wheel and assembling it on flanges, test the number of revolutions of the wheel spindle on the machinery at on the wheel indicated highest operational speed.

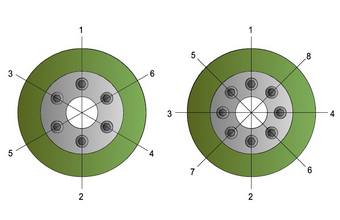

Machinery flanges should be clean and intact. Check also the condition of clamping screws, if all are of the same and appropriate quality. Between the machinery flange and the wheel, paper or PVC flanges which were delivered with the wheel are inserted. Clamping screws are equally tightened with a torque meter wrench in accordance with the below described steps.

Then follows a check of the balance of the wheel in case balancing needs to be performed. The quality of the ground surface depends also on the balance of the wheel and this is why the balance is important for achieving the optimal quality of the surface.

To statically balance your wheel, place the wheel on the polished shaft and then put it on the unit for balancing. With used wheels the balancing process might need to be repeated, depending on the wear and tear of the wheel.

In accordance with safety regulations and recommendations (ISO, DIN, FEPA), all wheels should be tested for operation before their first grinding. This testing of a newly set up wheel is done at the highest allowed speed. No KREBS&RIEDEL wheel should be used at speeds that exceed its highest allowed and in documents prescribed speed.

As specified in the DIN, ISO, FEPA and ANSI standards, every wheel should be operated in idle speed for at least one minute before grinding, while the peripheral speed should never exceed the recommendations of the manufacturer.

In production, x-times of the safety factor of the wheel against fracturing is ensured

Who is responsible for what

Manufacturer and distributor

At placing an order for a wheel with the type of grinding and machinery specifications, the producer determines the safety factor of the wheel.

In production, x-times of the safety factor of the wheel against fracturing is ensured. The safety factor depends on the grinding method and the machinery construction.

The testing of the flange speed and the safety factor are both performed already at the production plant. Fracturing tests are also done.

Every wheel is designated with appropriate product information, including the allowed operational speed. The producer or distributor needs to ensure suitable packaging free from any defects, but does not answer for any damages caused during transport or incorrect storage by the user.

Responsibilities of the machinery manufacturer

Guarantees a simple adjustment of the guiding device for workpieces and safety in reduced diameters of the wheel. Guarantees a limited number of revolutions of the wheel. Insures continuously variable regulators of the revolution number of the wheel. Guarantees the protection of machinery from particles which would generate in case of a fracturing of the wheel.

The flange construction should be appropriate for the assembly of the wheel in accordance with all the regulations.

User responsibilities

Takes care of proper storage. Inspects the wheel for any damages upon delivery and assembly, and respects all in the continuation required safety measures in assembling and preparing the wheel for its use.

Performs damage checks and the percussion test. Applies the appropriate machine flanges and wheel flanges by proper installation. Controls the wheel balance and safe operation at maximum allowed speed, and runs the wheel in idle speed before any grinding.

Assembles the guiding device, controls the fitting of the workpiece and takes care of safety. Never perform any alterations on grinding wheels in any respect.

Company

Brusilna tehnika d.o.o.

Masljeva ulica 3

1230 DOMŽALE

Slovenia

Phone.: +386 1 7291265

eMail: info@brusilnatehnika.si